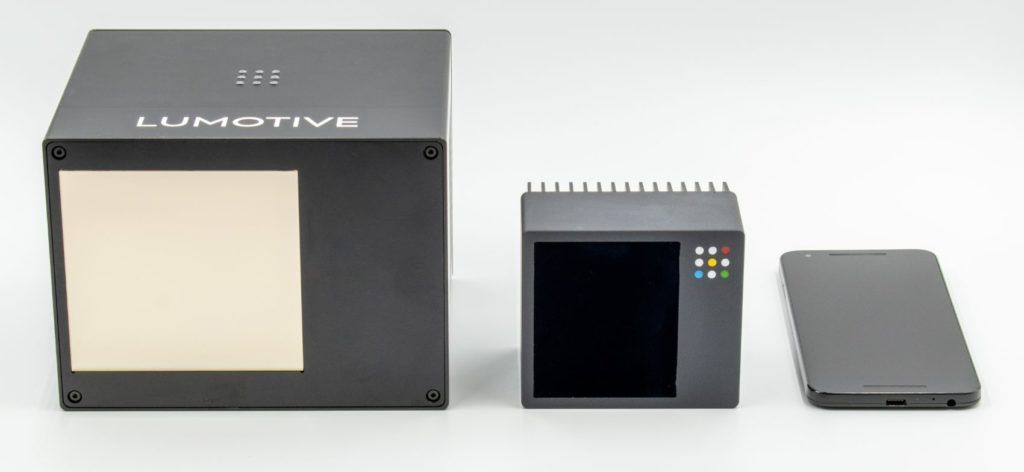

Lumotive recently announced the first of two in a series of 3D-sensing products that utilize Liquid Crystal Metasurfaces (LCM). With samples available in the fourth quarter of this year, the Lumotive X20 and Z20 LiDAR systems target the automotive and industrial automation markets, respectively. The X20 (extended range) and Z20 (lower range) originate from Lumotive’s X10 prototype of the same architecture.

“The X20 takes our learnings from the X10, but we shrink it down to something about a third of the size with better performance,” explained Lumotive co-founder and CEO, Dr. William Colleran. “The X20 is a long-range LiDAR, meaning it has upwards of 200 meters of range, but a vertical field of view of about 30 degrees.”

The X20 is designed for long-range automotive applications and can operate in bright sunlight with a 120° x 30° field of view. The Z20 will have a shorter range (~ 50 meters) but an expanded 70° vertical field of view to address industrial and short-range automotive needs.

“The Z20 is basically like the X20 but with different optics to expand the field of view,” Dr. Colleran added.

Who Is Lumotive?

Lumotive, a Seattle-based startup, arrived on the scene in 2018 after funding from Microsoft founder Bill Gates. The company specializes in LiDAR systems that employ beam-steering technology based on proprietary Liquid Crystal Metasurfaces (or LCMs). “This is our secret sauce,” Dr. Colleran said.

Lumotive unveiled its first LiDAR systems in the third quarter of last year. The company’s LCM chips contain no moving parts (solid-state) and are fabricated with mature semiconductor manufacturing and liquid crystal display packaging. Given LiDAR’s important role in the development of future ADAS and autonomous driving systems, Lumotive feels they are positioned to meet the demands of the market.

“The huge challenge of LiDAR is balancing performance, characterized by range, resolution and frame rate, with commercial viability as measured by size, reliability, and cost,” Dr. Colleran explained. “LCMs deliver the combination of performance and commercial viability that will finally eliminate barriers to adoption of LiDAR for both ADAS and autonomous vehicles.”

“A Gates-funded startup like Lumotive, with unique metamaterials-based technology, is well-positioned to serve this growing market,” added Alexis Debray, PhD., Technology & Market Analyst at Yole Développement. “The LiDAR markets dedicated to ADAS and robotic car applications are showing significant growth between 2019 and 2025, from U.S. $117 million to U.S. $2.3 billion.”

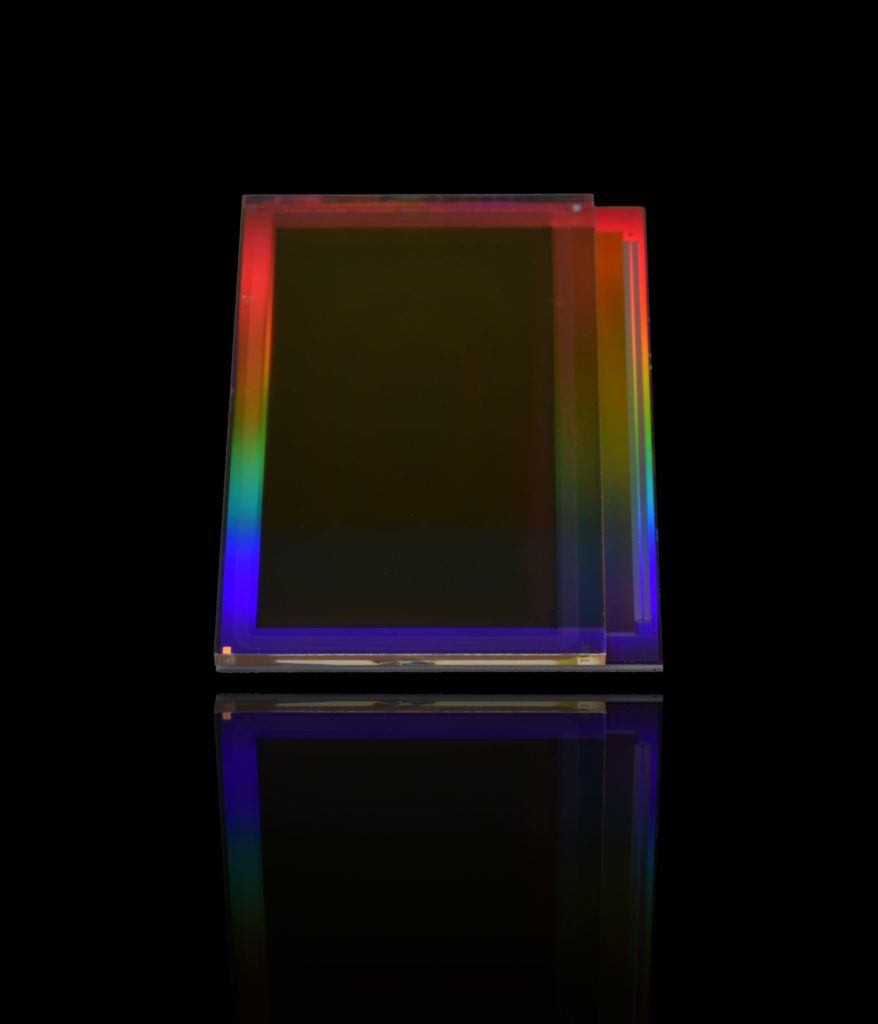

What Is a Liquid Crystal Meta Surface?

The idea of a metasurface is that you construct, on a surface, a number of resonators that resonate at the frequency or wavelength of operation of the electromagnetic radiation that you’re using. You space them so closely together that the surface, instead of appearing like a number of independent resonators, takes on a characteristic of looking like one object, so to speak. And you have to space them less than half a wavelength apart – that is key.

The idea is to take a semiconductor wafer and use the standard dielectric and metal materials that are used to interconnect a typical chip. We take the surface of this semiconductor wafer, which has all these structures built into it at nanoscale. We coat it with liquid crystal, so that when we apply electrical voltages to it in the appropriate pattern – those liquid crystals change the amount of phase delay that photons of light experience when they enter a resonator and then when they get re-radiated out.

So, we can control the phase delay in a pattern across the surface of the LCM. If we then illuminate the chip from a given angle, then by applying the appropriate pattern of voltages that interact with the liquid crystals in these resonators, we can cause the reflected signal to come off of the chip in the direction of our choosing.

You can think of it like a controllable mirror.

We are building a LiDAR system where you illuminate this metasurface with a laser. Then, when you apply the voltage pattern, you scan that laser out into the field of view. Reflected signals then come back from objects in that field of view and strike a second liquid crystal metasurface. That second metasurface is operated in lockstep with the first one so that only photons coming back from the direction you transmitted in are steered onto a detector array. ~ Lumotive co-founder and CEO, Dr. William Colleran, describing LCM operation.

The Benefit of Liquid Crystal Meta Surfaces

Lumotive employs LCMs to address challenges related to frame rate, commercial viability, size, cost, and ultimately performance and reliability. Dr. Colleran says LCMs, because of their large apertures, can better manage the performance “tradeoffs” when developing an optical system.

“In a LiDAR system, I want to see farther, so I want a larger aperture, but I also want a higher frame rate,” he said. “However, I don’t want to spend two minutes painting this picture, and then I get an update every two minutes. I want an update lickety-split.”

Dr. Colleran notes that a large aperture will return enough signal photons for an accurate measurement. By contrast, a smaller aperture returns a signal with too much noise so further measurements are needed. Those additional measurements must be averaged together to meet a signal to noise ratio that will reflect a robust and accurate reading. “Only then can I move to the next pixel,” Dr. Colleran said. “In almost any optical system, the larger the aperture, the better the performance.”

With the larger aperture, Lumotive achieves the desired range but does less averaging on account of gathering more photons on every measurement. “And therefore, you can increase your frame rate,” Dr. Colleran continued. “That’s just one example of how having a compelling advantage in one area can be traded off to give you the right balance of advantages in a host of different areas.”

Future Plans for Lumotive

Lumotive will expand its portfolio to include flexible LiDAR systems for both automotive and industrial applications. On the automotive side, Lumotive is investing in higher-range systems for faster-moving vehicles. When it comes to industrial applications, Lumotive is concentrating on shorter-range innovations to assist with low-speed vehicles like forklifts.

“We want to develop a breadth of LiDAR systems that can address different ranges and applications,” Dr. Colleran said. “We’re leveraging Moore’s Law to get better, faster, and cheaper, and we’re going to do that across a range of applications.”