ADAS Integration, Transforming the In-Cabin Experience, and the Initiative to Electrify are three of the automotive industry’s biggest megatrends. The drive to use advanced technology to enhance safety and in-cabin user experiences comes at the same time as electrification demands that vehicle energy usage be minimized. We look at how those designing and integrating in-car tech can ensure automakers are able to deliver on all three megatrends.

Three Automotive Megatrends: An Overview

If you’ve recently gone through the process of buying a new car, think back to why you selected it. It may have been cost, style, or comfort. And increasingly, consumers are also considering factors such as safety and fuel efficiency (or range in the case of an electric vehicle).

ADAS Integration

If you fall into the latter group, you’re not alone. A survey of U.S. adults found that fuel efficiency and safety were people’s two most important considerations when deciding on a new car. This consumer desire is shaping the first of three megatrends currently sweeping through vehicle design: advanced driver safety and automation (ADAS).

When you consider that a National Highway Traffic Safety Administration (NHTSA) statistical study found that 94 percent of all collisions are down to the driver, the importance of mitigating driver error where possible becomes clear.

Transforming The In-Cabin Experience

But it’s not just safety that consumers are focused on, leading us to the second automotive megatrend, transforming the in-cabin user experience. With all of us now used to the seamlessly connected digital experience we get with our phones, tablets, TVs, and gaming systems or in-home smart applications, buyers are looking for similar interactive environments from their cars.

The Initiative To Electrify

And thirdly, of course, there’s the initiative to electrify. In the United States, the goal is for 50 percent of vehicles sold to be electric by 2030. Other countries are even more ambitious. Norway, for example, widely regarded as a leader in environmental matters, has already passed this milestone. Likewise, VW recently announced it will no longer be selling new petrol or diesel models in the country – starting as soon as the beginning of 2024.

More broadly, many governments have pledged to end the sale of diesel and petrol cars by 2035.

The Paradox For Automakers & Equipment Designers

For those involved in designing and building the vehicles of tomorrow, these megatrends combine to create a unique and paradoxical cocktail of challenges, requiring a sophisticated blend of hardware and software to solve.

Why is it a paradox? The move to battery electric vehicles (BEVs) means energy usage needs to be minimized as much as possible to maximize range. At the same time, the other two megatrends, ADAS integration and the in-cabin experience, are driving up both the number of electronic components in the vehicle and the volumes of data that require power-hungry onboard processing.

As a result, modern vehicles are packed with multiple semiconductor components and silicon chips, from powerful microprocessors to innovative power management devices. Modern cars can contain between 1,500 and 3,000 semiconductors.

While some electrical systems can be lighter than their mechanical or hydraulic predecessors, care still needs to be taken to ensure the advances we’re seeing in battery technology aren’t unacceptably compromised by the use of electronics in the pursuit of better driver safety and automation and in-vehicle experiences.

For companies creating and integrating these electronics, the challenge is finding ways of delivering a raft of genuinely innovative automotive tech while keeping their prices competitive. This latter point is particularly important, given that price was the third-most essential buyer consideration in the study we referenced above.

Let’s look at how those designing and manufacturing components and systems to improve safety and automation, as well as the in-cabin experience, can ride the crest of these megatrend waves while ensuring high energy efficiency.

Improved Driver Safety & Higher Levels of Automation

Reducing reliance on the driver is critical to improving safety for all road users. This means our vehicles need better environmental perception to ultimately move up through the SAE’s levels of driving automation towards fully driverless operation.

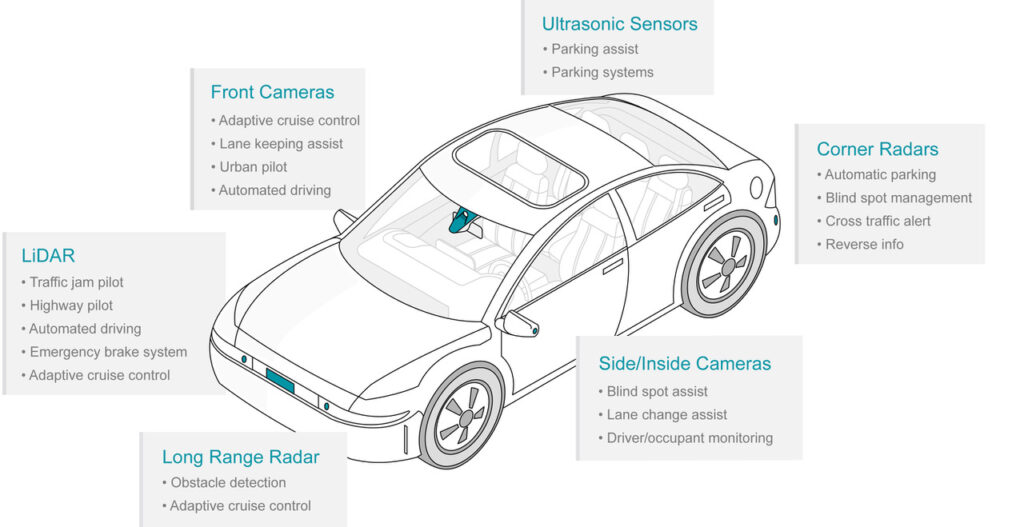

No single technology will suffice on its own, given the complexity of many road environments, the need for redundancy, and the simple fact that different technologies are good at different things. Most of us will already be used to parking sensors that use ultrasonic technology, adaptive cruise control (ACC) that leverages radar, and in-vehicle images of the surrounding environment for occupant and driver monitoring systems (OMS/DMS), made possible by imaging cameras.

One of the other key technologies being implemented is lidar, which uses lasers to build up a highly accurate image of the vehicle’s surroundings. To reduce the amount of energy required by lidar systems while also improving performance and reducing cost, we’re seeing a shift away from discrete field programmable gate array (FPGA) designs to mixed-signal systems-on-chip (SoCs), which combine digital signal processing (DSP) with analog-to-digital converters (ADCs).

The Role of Automotive Lighting

Another safety element is the advancement in exterior lighting, which assists the driver in seeing the roadway more clearly and enables imaging cameras to work more effectively.

Automakers are adopting dedicated controllers to deliver highly controllable and precise illumination (beam-forming) to create adaptive driving beams (ADBs) that light up as much of the road ahead as possible while minimizing glare for oncoming drivers and improving road safety.

The controllers deliver pixel-level resolution for ADB applications, allowing the headlights to provide precise, selective illumination of the way ahead. Lighting modules require banks of highly efficient MOSFETs to drive the LEDs with low losses and sophisticated pulse width modulation (PWM) to control the intensity of individual LEDs.

Enhancing The In-Cabin Experience

When we think about in-cabin user experiences, the first things that spring to mind are the in-vehicle infotainment (IVI) system and the instrument cluster. But there’s so much more than IVI that contributes to a positive in-cabin experience. Customers now expect to be able to connect their mobile devices to the IVI and charge them, both wired and wirelessly.

Electronically controlled utility and comfort systems are seeing increased rollout. While we are all familiar with electrically controlled seats, small motors are now electrifying a multitude of functions, such as air vents, seat ventilation, storage compartment doors, and seat belt buckle mechanisms. Automakers are even using interior lighting as a way to differentiate their products. Owners have the ability to adjust the in-vehicle ambiance to match their style preferences, the mood of the occupants, or the context of the journey.

To meet these demands, equipment makers and systems integrators need advanced, semiconductor-enabled LED technologies and smart lighting control systems. Dedicated driver integrated circuits (ICs) are now available, which incorporate intelligent modules based on efficient and flexible power management systems (often a step-down buck converter). These can drive as many as 24 LEDs, meaning a single IC can control multiple vehicle systems, from the instrument panel and interior lighting to external lights such as indicators or grille and logo lighting.

And at the heart of the system, you need a powerful microcontroller to provide communication to the rest of the vehicle, as well as other important functions such as ensuring color fidelity under all operating conditions.

Tomorrow’s Tech Is Here Today

Whether you’re in the business of building cars, integrating systems, or creating in-vehicle equipment, aligning your products with these three megatrends is essential if you’re to succeed. The challenge is to achieve the exceptional levels of energy efficiency required by electric vehicles while still delivering the improvements in safety, automation, and the in-cabin experience that today’s consumers demand.

The good news is that hardware solutions already exist to help meet the needs of all three megatrends, including SoCs, driver ICs, controllers, and more. And forward-thinking businesses are working closely with their automotive supply chain partners to select the right blend for their unique products.